Technologies

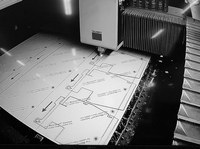

Laser Cutting

Precision laser cutting - CO2, fiber

- size of the sheet up to 3000 mm x 1500 mm

- cutting speed up to 52 m/minute

- accuracy +/- 0.1 mm

- power 5 kW

- steel, stainless steel, aluminium sheets to 25 mm

- brass and copper up to 10 mm

Punching

Precise cutting and punching of sheet metal

- sheet metal size up to 1500 x 3000 mm

- steel up to 3 mm

- stainless steel up to 3 mm

- aluminium and its alloys up to 4 mm

- the accuracy of punching and perforating is +/- 0.05 mm

- machine position accurancy is 0.02 mm

- in the case of highly visible parts we use sheets with protective foil and we also have a machine for straightening twisted sheets

Metal Bending

We bend sheet metal up to 4000 mm in length

- production tools from R 0,5 - R 40

- gradual bending of larger radiuses

- special tools

- bending without bend marks (visible parts) according to ISO 2768 tolerated dimensions

- 6-axis bending of complex parts

TRUMABEND V1300 press brakes

Bend length: up to 3000 mm

Pressing force: 1300 kN

TRUMABEND V200 press brake

Bend length: up to 4000 mm

Pressing force: 2000 kN

TRUMABEND V230 press brake

Bend length: up to 3000 mm

Pressing force: 2300 kN

TRUMABEND V85 S press brake

Bend length: up to 2500 mm

Pressing force: 850 kN

SAFAN 125/25T press brake

Bend length: up to 1250 mm

Pressing force: 250 kN

Amada HFP NT 220-30 NTL press brake

Bend length: up to 3100 mm

Pressing force: 2200 kN

Welding

We weld stainless steel, steel and aluminium materials

- EN 15085-2 Welding of railway rolling stock and components

- EN 1090-2 Fabrication of steel and aluminium structures

- EN 3834-2 Quality requirements for fusion welding of metallic materials

- 131 - MIG, manual welding

- 135 - MAG, manual welding and automated robot welding process

- 141, 142 - TIG, manual welding, partially mechanised orbital welding

- 21 - resistance spot welding

- 786 - condenser stud welding with stud ignition

- 783 - stroke welding of studs with ceramic ring

Metal Processing

Processing of workpieces up to 600 mm x 2000 mm

- accuracy up to 0.02 mm

- we also offer continuous 5-axis metal machining, including stainless steel materials

Liquid Painting

Certified and attested painting for exterior and interior by liquid painting method

- box size7x4 m

- box entrance opening 3x2,5 m

- maximum weight of 1 piece is 500 kg

- possibility of painting with multilayer systems including paint rubbing into engraved reliefs

- painting of stainless steel, Al, Fe materials including plastics

- pretreatment for painting by ferric phosphate or by blasting

Powder Painting

Powder coating of all types of metal, aluminium and galvanized materials

- manual pretreatment with ferric phosphate

- manual electrostatic or electrokinetic painting

- possibility of two-layer painting with anticorrosive primers

- masking of functional surfaces

- max. product dimensions 1600x1900x4000 mm max. weight 160Kg

- possibility of corrosion tests - salt spray, impact test, sandwich test

- DEMI water production

3D Measuring

Measuring a part on the XOrbit 87 3D gauge

- XOrbit 87 measuring machine

- accuracy up to 0.005 mm

- possibility to produce a report in graphical or numerical form