SV metal - custom processing of sheet metal, development and production of single-purpose machines and equipment

Why choose SV metal?

We are stable company with more than 20 years of experience in the field of single-part and small batch production. Production flexibility provided by several centres. Quality guaranteed by ISO certificates from TÜV.

We realize everything from production preparation (design and technology) through the actual production to surface finishing including service.

We deliver simple products within 1-4 weeks, more complex products depending on their difficulty.

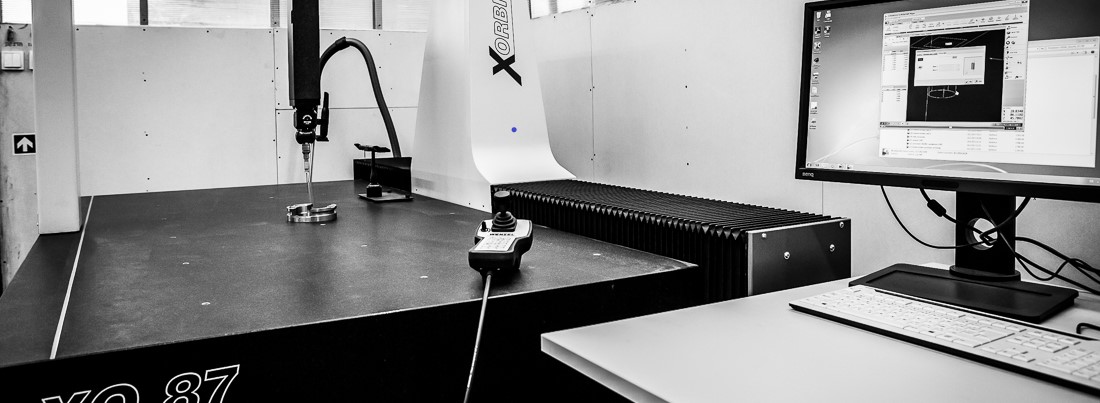

We ensure quality by means of ISO 9001 quality management system, for welding according to EN 15085-2 and for environmental protection according to ISO 14001.

We continuously evaluate the fulfilment of delivery deadlines. We consistently achieve values greater than 95%.

The number of our significant customers speaks for this indicator. We export more than 85% of our production.

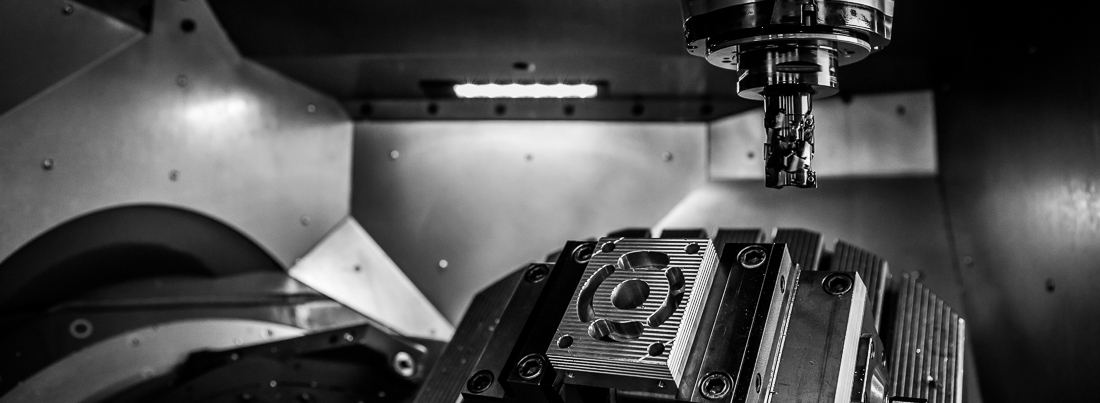

To handle our wide product portfolio we have CNC machine tools, fiber laser, engraving, welding of almost all types of materials.

We are constantly developing new products such as tool grinders, hydraulic assembly presses, robotic workstations and more.

We treat our customers as partners and this is why we are able to establish and maintain long-term relationships with them.